Key Points on How to Select the Right Drilling Rigs

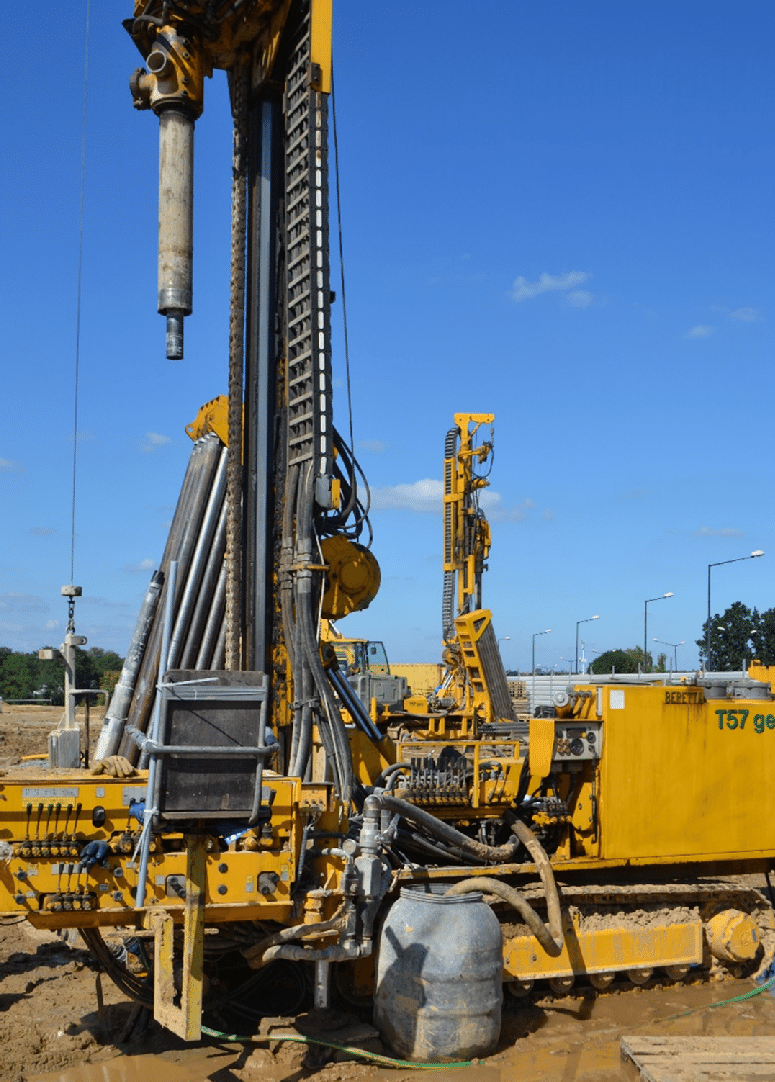

Finding the right drilling rigs for a particular job is the most important decision that every driller must make since it will have an impact on the overall drilling performance.

With the growing and expanding drilling industry, finding the best rig to drill with is easier said than done. Aside from the type of ground, other factors must be considered, including the contractor, their expertise, machine cost, safety, and service aftermarket.

To simplify this task, we have compiled some key points on selecting the right drilling equipment. Keep reading on!

Factors to Consider When Choosing New Drilling Rigs

Machine Price

Buying a new drilling rig is considered a one-time investment that needs careful deliberation. For most drillers, the price of the equipment is a vital factor when selecting a drilling rig. Drillers should be aware that the machine’s price increased along with increasing hole diameter and depth.

The system or the technology utilized in drilling equipment is also a contributing factor. For instance, a DTH drilling rig is more expensive than a coring drilling rig, while the price of a hydraulic drilling rig is higher than a vertical shaft drilling rig, which is a more mechanical drilling machine. And in terms of mobility, truck-mounted rigs cost more than crawler-mounted drill rigs.

The bottom line is that finding the right drilling equipment and selecting the best option available are key steps in building a strong drilling business. At the end of the day, it all comes down to what’s most practical to the wallet of the driller, the kind of drilling to be done, and the geology or the terrain of the job sites.

Drilling Efficiency

Another significant factor that every drilling must consider is the drilling efficiency of the equipment. Every driller must note that the efficiency of the rig depends on the stratum, skills or experience of the operator, and the type of drilling machine and drilling method.

Hence, the geology or the condition of the job site must be analyzed very well to select the right equipment that will provide better results and profitability through efficient drilling.

Safety and Ease of Use

In every drilling operation, safe working conditions are non-negotiable. The safety of the workers should be a top priority when selecting drilling equipment, including safety for a rig operator, service people as well as people around the rig during a drilling operation.

Service after Market

Choosing a contractor or manufacturer with excellent service after market and support is another point for drilling rig selection.

There are a lot of potential issues that may arise during the drilling operation, a contractor must be able to handle these breakdowns in a timely and professional way. Otherwise, it will affect the owner’s drilling business.

Availability of Spare Parts

The last important factor that needs to be considered during rig selection is the availability of spare parts. Drillers need to consider this when buying drilling equipment as part of operational costs.

If the spare parts are not readily available or may take time to get them, it means that you have to pay more and wait a long time before getting the needed parts. Again, this will affect your drilling business profitability.

In Conclusion

We all realize that choosing the right drilling equipment is the most important decision and will have a major impact on your drilling business.

The key points mentioned above are just some of the basic information during drilling equipment selection. They can be used as a guide for business starters when they plan to buy their first drilling rig.

We also highly suggest that you select a drill rig company with broad experience, resources, and expertise in the business.

Key Points on How to Select the Right Drilling Rigs Read More »

Finding the right drilling rigs for a particular job is the most important decision that every driller must make since it will have an impact on the overall drilling performance.

With the growing and expanding drilling industry, finding the best rig to drill with is easier said than done. Aside from the type of ground, other factors must be considered, including the contractor, their expertise, machine cost, safety, and service aftermarket.

To simplify this task, we have compiled some key points on selecting the right drilling equipment. Keep reading on!

Factors to Consider When Choosing New Drilling Rigs

Machine Price

Buying a new drilling rig is considered a one-time investment that needs careful deliberation. For most drillers, the price of the equipment is a vital factor when selecting a drilling rig. Drillers should be aware that the machine’s price increased along with increasing hole diameter and depth.

The system or the technology utilized in drilling equipment is also a contributing factor. For instance, a DTH drilling rig is more expensive than a coring drilling rig, while the price of a hydraulic drilling rig is higher than a vertical shaft drilling rig, which is a more mechanical drilling machine. And in terms of mobility, truck-mounted rigs cost more than crawler-mounted drill rigs.

The bottom line is that finding the right drilling equipment and selecting the best option available are key steps in building a strong drilling business. At the end of the day, it all comes down to what’s most practical to the wallet of the driller, the kind of drilling to be done, and the geology or the terrain of the job sites.

Drilling Efficiency

Another significant factor that every drilling must consider is the drilling efficiency of the equipment. Every driller must note that the efficiency of the rig depends on the stratum, skills or experience of the operator, and the type of drilling machine and drilling method.

Hence, the geology or the condition of the job site must be analyzed very well to select the right equipment that will provide better results and profitability through efficient drilling.

Safety and Ease of Use

In every drilling operation, safe working conditions are non-negotiable. The safety of the workers should be a top priority when selecting drilling equipment, including safety for a rig operator, service people as well as people around the rig during a drilling operation.

Service after Market

Choosing a contractor or manufacturer with excellent service after market and support is another point for drilling rig selection.

There are a lot of potential issues that may arise during the drilling operation, a contractor must be able to handle these breakdowns in a timely and professional way. Otherwise, it will affect the owner’s drilling business.

Availability of Spare Parts

The last important factor that needs to be considered during rig selection is the availability of spare parts. Drillers need to consider this when buying drilling equipment as part of operational costs.

If the spare parts are not readily available or may take time to get them, it means that you have to pay more and wait a long time before getting the needed parts. Again, this will affect your drilling business profitability.

In Conclusion

We all realize that choosing the right drilling equipment is the most important decision and will have a major impact on your drilling business.

The key points mentioned above are just some of the basic information during drilling equipment selection. They can be used as a guide for business starters when they plan to buy their first drilling rig.

We also highly suggest that you select a drill rig company with broad experience, resources, and expertise in the business.