3D Printing Perth: Creating More Viable Ways for the Energy Industry

Manufacturers across different industries are looking for the best business solutions that provide them with the highest quality possible at a lower cost.

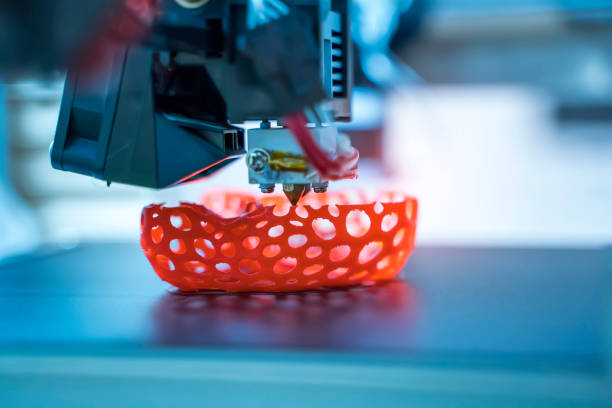

The one that stands out is 3D printing or also called additive manufacturing. This fast-emerging technology has revolutionized major industries, from consumer goods and medical to automotive and aerospace.

Seeing the potential benefits and advantages of 3D printing, manufacturing companies and organizations around the globe are increasingly embracing and investing in this technology. One industry that stands to gain heavily from additive manufacturing is the energy sector.

As the global concern over climate change rises, the demand for renewable and sustainable energy sources also increases. However, one of the biggest challenges of the companies in this sector is the complex equipment needed to harness natural energy sources such as wind and solar energy and turn them into power for their consumers.

As a potential solution to this problem, 3D printing Perth plays an important role in the success of the energy industry through its ability to quickly develop tailored, mission-critical components that can withstand extreme conditions.

In this article, we will be discussing the different applications and advantages of additive manufacturing as it strives to empower the energy industry to become more efficient and innovative.

3D Printing Applications for Energy Industry

Building High-Resolution Prototypes Faster

The success of 3D printing in the energy sector hinges on delivering high-resolution prototypes quickly while carrying out more reliable tests.

Energy companies utilizing additive manufacturing can create a working prototype at a lesser lead time, depending on the result of the initial simulation.

This faster approach of 3D printing to making prototypes can help refine energy projects a lot faster, at a lower cost, and thus decrease time to market.

Production of Complex End-Use Parts

Employing 3D printing technology to manufacture complex end-use parts is one of the mainstream operations in the energy industry.

The ability of this method to create custom, complex parts faster than the traditional manufacturing methods has convinced the engineers to utilize this technology as a perfect solution for low-volume projects.

Also, additive manufacturing does not require any tooling. And it can produce lightweight structures with complex internal features, which is an important element in the next generation of energy sources.

Manufacturing of Spare Parts

Another significant application of additive manufacturing in the energy sector is spare parts manufacturing. During mechanical breakdown, manufacturers do not solve the problem by replacing the entire equipment, unlike with aging models where manufacturers tend to discontinue using them.

With the help of this technology, manufacturers can easily make up for supply-chain challenges and fabricate the spare parts they need on-site without over-burdening their stocks with hoarded spare components.

Types of Energy Applications Produced with 3D Printing Perth

- Fluid/water flow analysis

- Rotors

- Flow meter parts

- Turbine nozzles

- Pump manifolds

- Jigs and fixtures

- Mud motor modules

- Pressure gauge pieces

- Control-valve components

Future of 3D Printing in Energy Sector

Additive manufacturing brings so much potential when it comes to innovation in the energy sector. As energy companies continue to explore and utilize these potential and benefits in their supply chains, 3D printing has a significant growth to be seen as an efficient solution for the energy industry’s complex needs.

3D Printing Perth: Creating More Viable Ways for the Energy Industry Read More »

Manufacturers across different industries are looking for the best business solutions that provide them with the highest quality possible at a lower cost.

The one that stands out is 3D printing or also called additive manufacturing. This fast-emerging technology has revolutionized major industries, from consumer goods and medical to automotive and aerospace.

Seeing the potential benefits and advantages of 3D printing, manufacturing companies and organizations around the globe are increasingly embracing and investing in this technology. One industry that stands to gain heavily from additive manufacturing is the energy sector.

As the global concern over climate change rises, the demand for renewable and sustainable energy sources also increases. However, one of the biggest challenges of the companies in this sector is the complex equipment needed to harness natural energy sources such as wind and solar energy and turn them into power for their consumers.

As a potential solution to this problem, 3D printing Perth plays an important role in the success of the energy industry through its ability to quickly develop tailored, mission-critical components that can withstand extreme conditions.

In this article, we will be discussing the different applications and advantages of additive manufacturing as it strives to empower the energy industry to become more efficient and innovative.

3D Printing Applications for Energy Industry

Building High-Resolution Prototypes Faster

The success of 3D printing in the energy sector hinges on delivering high-resolution prototypes quickly while carrying out more reliable tests.

Energy companies utilizing additive manufacturing can create a working prototype at a lesser lead time, depending on the result of the initial simulation.

This faster approach of 3D printing to making prototypes can help refine energy projects a lot faster, at a lower cost, and thus decrease time to market.

Production of Complex End-Use Parts

Employing 3D printing technology to manufacture complex end-use parts is one of the mainstream operations in the energy industry.

The ability of this method to create custom, complex parts faster than the traditional manufacturing methods has convinced the engineers to utilize this technology as a perfect solution for low-volume projects.

Also, additive manufacturing does not require any tooling. And it can produce lightweight structures with complex internal features, which is an important element in the next generation of energy sources.

Manufacturing of Spare Parts

Another significant application of additive manufacturing in the energy sector is spare parts manufacturing. During mechanical breakdown, manufacturers do not solve the problem by replacing the entire equipment, unlike with aging models where manufacturers tend to discontinue using them.

With the help of this technology, manufacturers can easily make up for supply-chain challenges and fabricate the spare parts they need on-site without over-burdening their stocks with hoarded spare components.

Types of Energy Applications Produced with 3D Printing Perth

- Fluid/water flow analysis

- Rotors

- Flow meter parts

- Turbine nozzles

- Pump manifolds

- Jigs and fixtures

- Mud motor modules

- Pressure gauge pieces

- Control-valve components

Future of 3D Printing in Energy Sector

Additive manufacturing brings so much potential when it comes to innovation in the energy sector. As energy companies continue to explore and utilize these potential and benefits in their supply chains, 3D printing has a significant growth to be seen as an efficient solution for the energy industry’s complex needs.

3D printing is essential that will certainly permit the manufacturing sector to reach its best capacity- mass personalization, dispersed production, and complete procedure control. Today, 3D printing is altering manufacturing by shortening turnaround time, decreasing price for reduced volume manufacturing, and supporting intricate styles which are difficult to create using traditional production methods.

3D printing is essential that will certainly permit the manufacturing sector to reach its best capacity- mass personalization, dispersed production, and complete procedure control. Today, 3D printing is altering manufacturing by shortening turnaround time, decreasing price for reduced volume manufacturing, and supporting intricate styles which are difficult to create using traditional production methods.