Everything in our lives calls for an examination and, for the most part, regular maintenance. This ensures appropriate performance when needed. Human health requires regular check-ins and intense demands like hydration, consumption, and sleep. Our vehicles, residences, and every other living system need standard treatment. You would certainly not allow your body, cars, truck, or home to do without the required things, so why let your compressed air system? Missing air compressor repairs and upkeep requirements lead to more costs in one way or another, whether it is replacing a component or the whole machine.

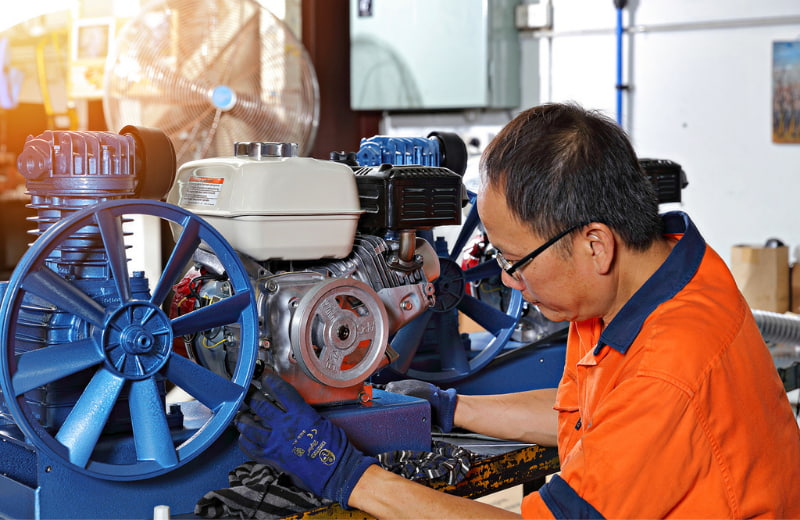

Air Compressor Repairs and Maintenance

It is not various in the case of a manufacturing facility, medical facility, refinery, food factory, auto solution shop, or any other place that requires their systems and equipment to work and execute when needed. Uptime and also performance are crucial aspects in every market. All manufacturers have a minimum required solution or upkeep period for their items. Created by industry experts with experience in applications across the board, these criteria are an asset to the end-user.

The compressor system is not different from the scenarios mentioned above. Air compressors in a center or store are a crucial part similar to various other energies. The tools, controls, shutoffs, production devices, and so on that need pressed air from the design all depend on its availability on demand. If the machine runs without being kept an eye, it can overheat and close down.

If the filters are not changed at routine intervals, the distinction in pressure (Delta P) raises operating expenditures. The greater the warm tons from lack of maintenance additionally reduces the life of the compressor lubricant. This will call for more frequent changes and costs added to replace and throw away the used oil.

Improved operating temperature levels can trigger a wide range of problems. The internal components will be too soon used, and the electrical motor would undoubtedly go for higher amperages, which is a much higher operating expense; plus, the engine is in danger of premature failure under such problems. It can add even more condensate being generated within the system. This needs the drains to be functioning to efficiently get rid of the water and also ensure it goes into the production side through the piping system.

Another necessary reason for doing required routine maintenance is security. This helps prevent tragic failures like a fire. It is not unusual to witness compressors shutting down due to high temperatures. In most cases, if routine treatment was finished, such interruptions and expensive occurrences may have been avoided.

Proper regular maintenance can conserve production costs and time. When failings or unplanned downtime occurs, it comes to be an emergency. The cost of service, repair work, components, manufacturing, and losses increase considerably.

The crucial benefits of doing called-for compressor preemptive upkeep are cost financial savings, lowered device downtime, boosted security and reliability, and peace of mind from securing your properties.

Regular Upkeep Tasks to Execute on Your Compressor

Drive belts, inlet air filters, and lubricating oil must be inspected and changed regularly. It is also expected to include “makeup” oil due to oil carry-over and doing so often endure the device. Synthetics are prevalent in the lubrication of compressors and reduce regular wear and buildup inside. The lubes cool down and clean up as they help protect the possession. They also lower the modification intervals, which subsequently conserve cash and time.