Experience a Satisfying and Efficient Drilling with a Comacchio Drill Rig

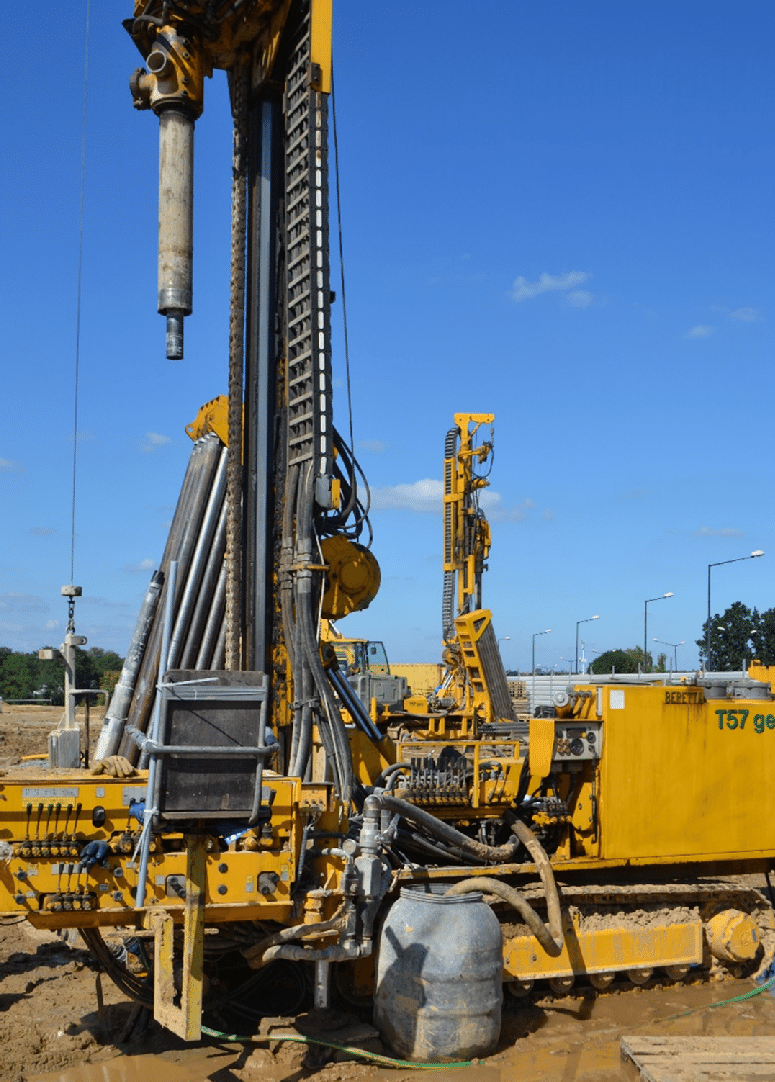

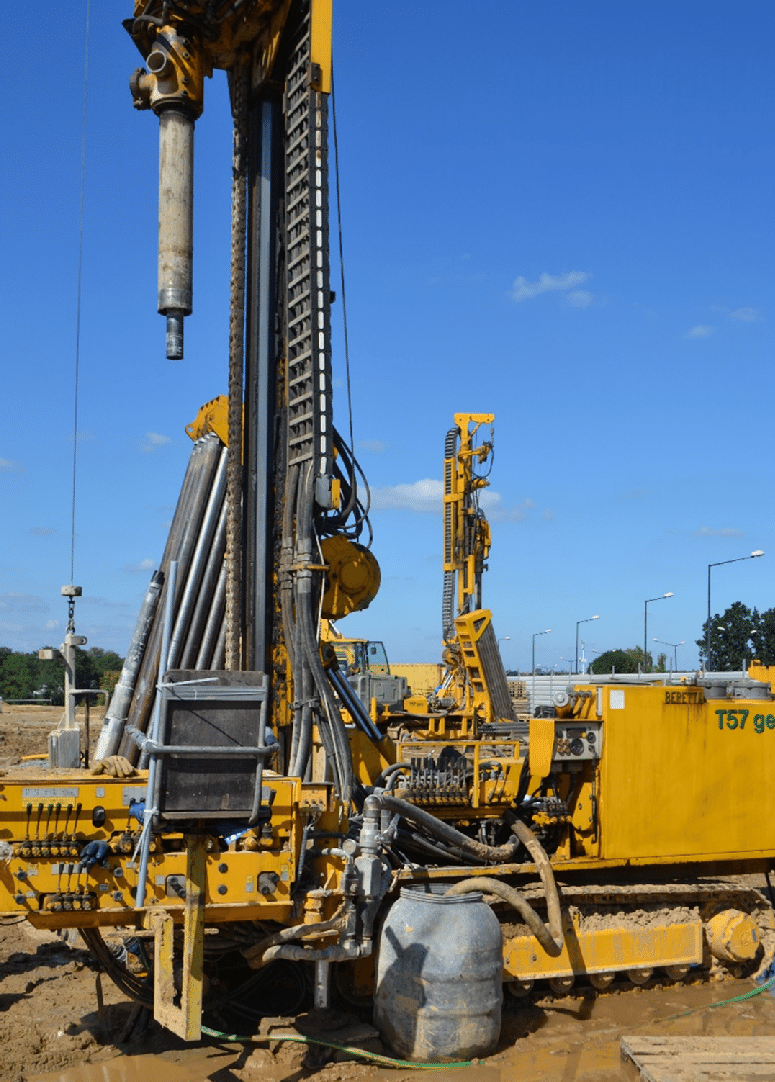

If you seek high-quality equipment that provides satisfying and efficient results for various drilling operations, such as geotechnics, foundations, ground improvements, water well drilling, geothermal, and exploration, a Comacchio drill rig is the right equipment for you.

With over 30 years of expertise and continuous innovation, Comacchio offers a wide variety of products that provide tailor-made solutions to suit the specific need of every driller.

As the leading manufacturer of quality and innovative geotechnical drilling rigs, Comacchio’s range of drilling rigs has evolved to suit unique site conditions, the latest drilling methods, and industry standards.

So, what really makes Comacchio the drill of choice for many companies and firms? Well, have a read and see for yourself.

Comacchio Drill Rig – GEO Line

The GEO line includes hydraulic crawler-mounted drilling rigs for geotechnics, environmental studies, sample collection, and water well drilling.

Also, this line of compact-sized equipment includes medium-sized machines suitable for water well drilling rigs.

This fleet of drilling rigs uses an advanced modular hydraulic circuit to ensure high performance and allows the installation of a variety of rotary heads and hydraulic drifters, enabling the drilling rigs of GEO Line to operate all rotary drilling systems, coring, rotary-percussive and wire-line systems.

Lastly, the GEO line is customizable thanks to a comprehensive selection of accessories that helps in meeting the specific application needs, soil features, and job-site conditions.

Top Applications of Comacchio GEO Line Drill Rigs

This particular line of drilling rigs is versatile enough to meet the diverse requirements and needs connected to any geotechnical site investigation project.

The wide range of models installed on crawler tracks, ranging from lightweight and small footprint units are suitable for small geotechnical site investigations and environmental drilling projects inside buildings or in areas with constrained space to heavy-duty machines.

The Comacchio GEO rigs have flexible designs and utilize an extensive choice of rotary equipment and onboard accessories to guarantee that each structure combines the ability to perform multiple drilling types from the same rig.

Moreover, this GEO line can be aligned for Sonic drilling to conduct ground investigations in challenging site conditions.

These multipurpose units perform the following:

• Generate core samples with superior quality

• Implement percussive sampling

• Conduct in situ mechanical property testing

• Install borehole instrumentation for long-term monitoring of ground conditions

• Carry out deep wire-line coring

• Conduct open-hole drilling techniques

Regardless of operational limitations due to access, confined space, emission controls, etc., the GEO Line Drill Rigs can offer a wide range of solutions for your drilling needs.

Summary

Comacchio’s line of drilling rigs is of high quality and efficient equipment that entirely satisfies the types of customers operating within the drilling market.

This fleet of drill rigs has considerable advancement in drilling technology applicable to multiple industries, including infrastructure, construction and development, mining, and environmental exploration.

Experience a Satisfying and Efficient Drilling with a Comacchio Drill Rig Read More »

If you seek high-quality equipment that provides satisfying and efficient results for various drilling operations, such as geotechnics, foundations, ground improvements, water well drilling, geothermal, and exploration, a Comacchio drill rig is the right equipment for you.

With over 30 years of expertise and continuous innovation, Comacchio offers a wide variety of products that provide tailor-made solutions to suit the specific need of every driller.

As the leading manufacturer of quality and innovative geotechnical drilling rigs, Comacchio’s range of drilling rigs has evolved to suit unique site conditions, the latest drilling methods, and industry standards.

So, what really makes Comacchio the drill of choice for many companies and firms? Well, have a read and see for yourself.

Comacchio Drill Rig – GEO Line

The GEO line includes hydraulic crawler-mounted drilling rigs for geotechnics, environmental studies, sample collection, and water well drilling.

Also, this line of compact-sized equipment includes medium-sized machines suitable for water well drilling rigs.

This fleet of drilling rigs uses an advanced modular hydraulic circuit to ensure high performance and allows the installation of a variety of rotary heads and hydraulic drifters, enabling the drilling rigs of GEO Line to operate all rotary drilling systems, coring, rotary-percussive and wire-line systems.

Lastly, the GEO line is customizable thanks to a comprehensive selection of accessories that helps in meeting the specific application needs, soil features, and job-site conditions.

Top Applications of Comacchio GEO Line Drill Rigs

This particular line of drilling rigs is versatile enough to meet the diverse requirements and needs connected to any geotechnical site investigation project.

The wide range of models installed on crawler tracks, ranging from lightweight and small footprint units are suitable for small geotechnical site investigations and environmental drilling projects inside buildings or in areas with constrained space to heavy-duty machines.

The Comacchio GEO rigs have flexible designs and utilize an extensive choice of rotary equipment and onboard accessories to guarantee that each structure combines the ability to perform multiple drilling types from the same rig.

Moreover, this GEO line can be aligned for Sonic drilling to conduct ground investigations in challenging site conditions.

These multipurpose units perform the following:

• Generate core samples with superior quality

• Implement percussive sampling

• Conduct in situ mechanical property testing

• Install borehole instrumentation for long-term monitoring of ground conditions

• Carry out deep wire-line coring

• Conduct open-hole drilling techniques

Regardless of operational limitations due to access, confined space, emission controls, etc., the GEO Line Drill Rigs can offer a wide range of solutions for your drilling needs.

Summary

Comacchio’s line of drilling rigs is of high quality and efficient equipment that entirely satisfies the types of customers operating within the drilling market.

This fleet of drill rigs has considerable advancement in drilling technology applicable to multiple industries, including infrastructure, construction and development, mining, and environmental exploration.